Interesting video, this is far from resolving all the world's issues of course, this is essentially throwing a bunch of plastic in a tube and microwaving it to extreme temperatures, but it can create a ton of graphene (30mg plastic -> 5mg graphene conversion). The proposed use for this graphene is in cement mixes in order to toughen concrete and reduce wear on roads and structures.

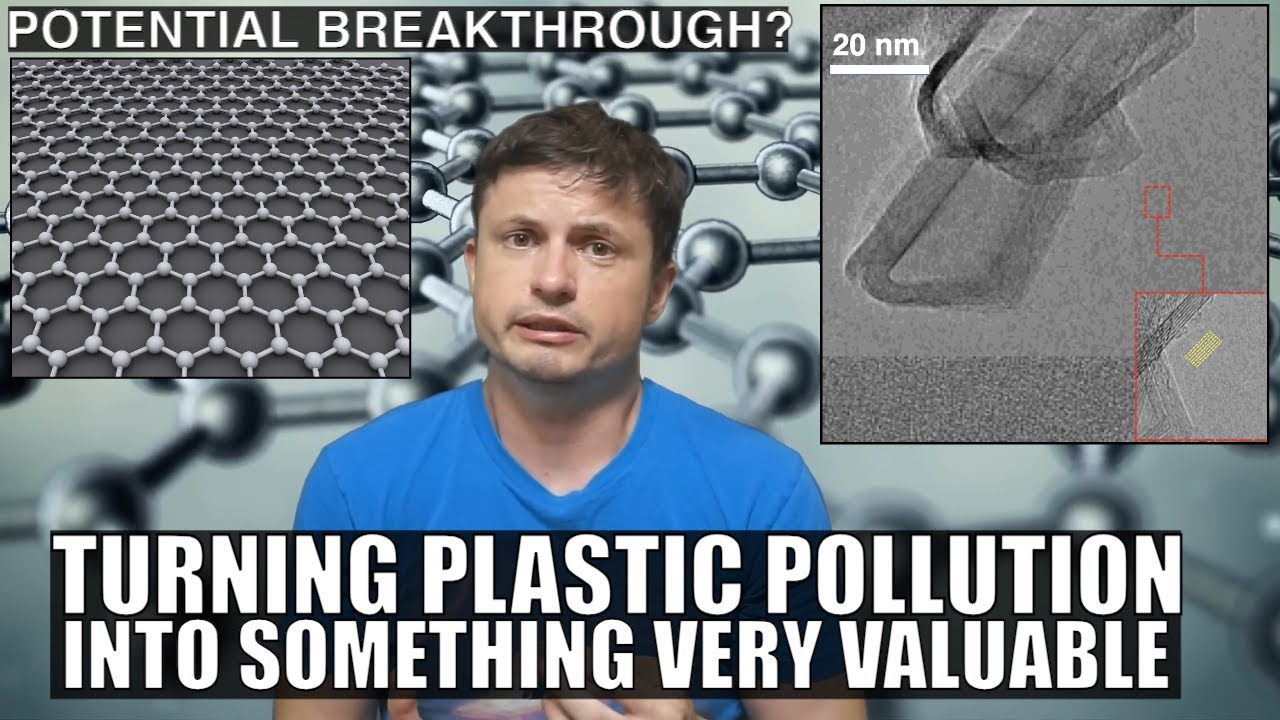

The technique uses flash Joule heating (FJH) to heat carbonaceous materials to temperatures over 3000 K in ∼100 ms, producing >90% yields of high quality turbostratic FG (tFG). The high temperatures of FJH result in high purity tFG, since much of the non-carbon atoms are removed through sublimation

Using this much energy is of course problematic, sure, it can get rid of the plastic, but we are largely burning fossil fuels to create this energy. It takes 400-600w of electricity to produce this much graphene, which is certainly a breakthrough for graphene production, at least, because of how labor cheap this is. Its also much cheaper electricity wise than pretty much every pre-existing recycling method, which is certainly a good thing.

In this study, the goal is to broaden the application of APMP to solid precursors, specifically converting microplastics into graphene. In contrast to the traditional method of initiating graphene production from gaseous-phase products, this approach involves the transformation of PE microplastics into gases such as methane, ethylene, and ethane, and then converting them into graphene within the plasma, all in one step. Furthermore, the advantages of microwave-based technologies in terms of energy consumption and cost compared to conventional techniques for recycling or upcycling polymers can be found in recently reported studies.[27-29] Following the successful synthesis of graphene, we also showcase its effectiveness in adsorbing perfluorooctanoic acid (PFOA), facilitated by ultrasonication.

The beauty of this is you don't have deep concerns about offgassing, the plasma captures the most harmful vapors and flash converts them to a graphene powder, which resolves a concern of harmful contaminates to local areas of production. It will mostly offgas H2, Carbon monoxide, and Co2, though the paper doesnt seem to discuss the quantities of each gas it produces. Co2 offgassing is obviously problematic itself if that quantity is very high, you're essentially turning a lot of the 'stored' co2 in plastic into gas in the atmosphere. Based on similar studies, it does seem that it will off gas far more H2 than CO or CO2 though

tl:dr: some scientists got a tube filled it with argon and smashed up microplastics, chucked it in a 500 watt microwave, and got a way to make a lot of money off of graphene synthesis

Neat! Graphine is a pretty cool material with the issue of trying to make large quantities of of it. I'm guessing this is solely as concrete mix and not something that can be used to make stuff like graphine cables/rope?

afaik it can be used for normal processes, theres a concrete shortage issue though and graphene would help